- GST NO. : 24AADCF2745D1Z2

- Send Email

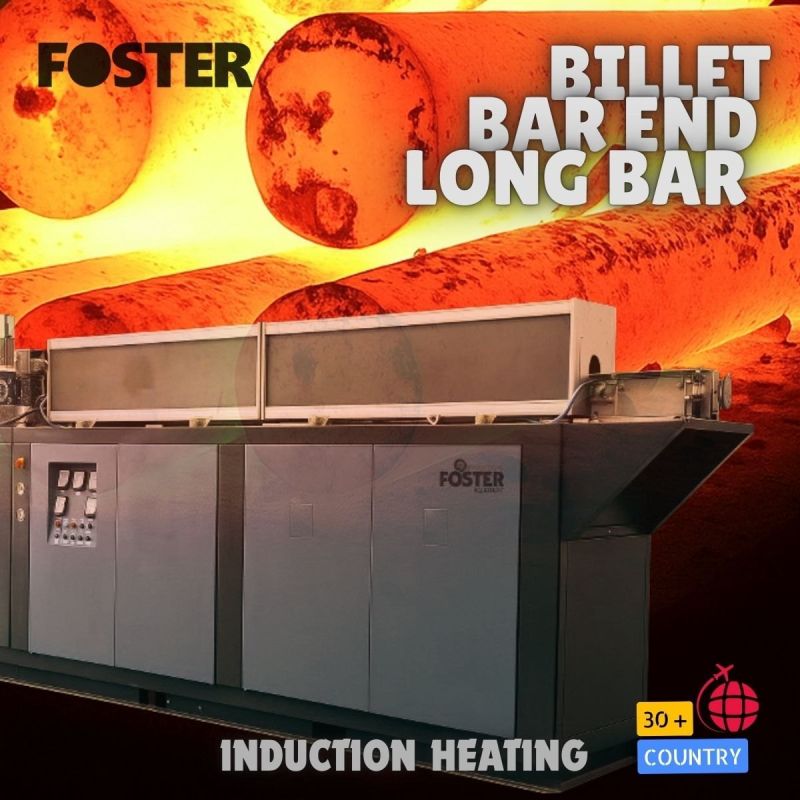

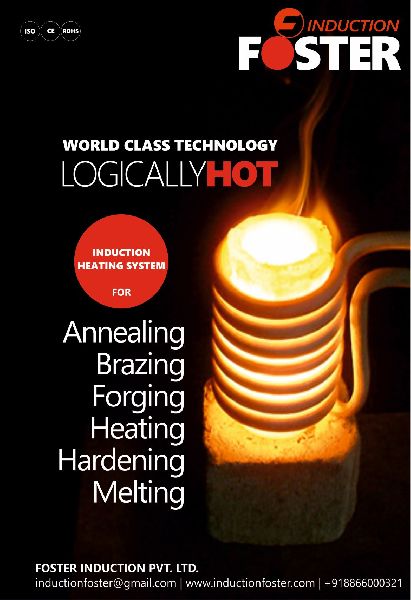

Induction Heating Machine

Leading Manufacturers, Exporters, Wholesaler, Retailer of Induction Bar End Heater, Induction Bearing Heater, Induction Billet Heater, Induction Bolt Heating Machine, Induction Heating Equipment and Induction Heating Equipment for Copper Wire Stripping from Rajkot.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Type | Induction Bar Heater |

| Brand Name | Foster |

| Certification | ISO 9001:2008 |

| Weight in Kg | 85 Kg |

| Voltage | 420 |

| Condition | New |

| Application | Industrial Use |

| Power Source | Electric |

| Color | Grey And Multiple |

| Automatic Grade | Semi Automatic |

| Packaging Type | Wooden |

| Frequency | 50/60 Hz |

| Size | Compact |

| Heater Material | Iron, Steel, Copper, Brass |

| Payment Terms | Other |

| Packaging Details | Wooden |

Induction bar-end heating equipment is available for many sizes and shapes.Multiple bar ends can be heated using differing types of induction coils. The powerful combination of advanced engineering, product innovation and continuous research in induction heating has made us the leading manufacturer and exporters in billet and end bar heating equipment. Induction bar-end heating equipment is available for many sizes and shapes.Multiple bar ends can be heated using differing types of induction coils. The powerful combination of advanced engineering, product innovation and continuous research in induction heating has made us the leading manufacturer and exporters in billet and end bar heating equipment.

| Business Type | Manufacturer, Exporter |

| Voltage | 230V AC |

| Heater Material | Bearing |

| Power | 2.5 KVA |

| Brand | Foster |

| Size | Compact |

| Current | 12Amp Maximum |

| Bearing Inner Diameter | 25mm to 120mm |

| Model Name/Number | FBH1 |

| Temperature | 140d |

| Auto Adjustment | Micro Controller Based Automatic |

| Business Type | Manufacturer, Exporter |

| Brand Name | Foster |

| Material | Mild Steel |

| Color | Silver |

| Power | 15kW - 100kW |

| Power Source | Electric |

| Certification | RoHS |

| Voltage | 380-420 V |

| Packaging Type | Wooden |

| Type | Induction Heaters |

| Frequency | 50-60 Hz |

| Phase | 3 Phase |

| Warranty | 1 Year |

| Country of Origin | India |

| Automation Grade | Semi Automation |

| Usage/Application | Induction Billet Heating Forging Furnace |

| Heater Material | Steel, Brass, Copper, Iron |

| Surface Treatment | Powder Coated |

| Port | Mundra |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, Other |

| Delivery Time | 28 - 30 days |

| Packaging Details | Wooden Packaging. |

In the induction billet heater the whole of the billet or slug is heated. Normally for short billets or slugs a hopper or bowl is used to automatically present the billets in line to pinch rollers, chain driven tractor units or in some cases pneumatic pushers.Heater Material: Steels, Brass, Aluminum, Copper etc.Power(Watts): 7.5 kw- 100 kwInduction heating saves the time to heat the part.Induction heating will greatly improve the quality of Brass and Copper alloy billets when it will be pressed.Heaters can be configured as single billet or multi-billet induction coils dependent on the production rates required.

| Business Type | Manufacturer, Exporter |

| Country of Origin | India |

| Type | Heating Machines, Industrial Heating Machine, Bolt Heating Machine |

| Certification | ISO 9001:2008, CE |

| Application | Heaters |

| Weight | 85 Kg |

| Color | Grey |

| Voltage | 230V |

| Condition | New |

| Automatic Grade | Semi-Automatic |

| Power | Electric |

| Warranty | 1year |

| Brand Name | Foster |

| Material | MS/ Iron Nut Bolt |

| Size | Portable |

| Heater Material | MS/Iron Nut Bolt |

| Frequency | High |

| Product Type | Induction Nut Bolt Heater |

| Payment Terms | Other |

| Delivery Time | 28 - 30 days |

| Packaging Details | Wooden |

What is induction bolt heating?Expanding bolts with induction is the proven time- and labour-saving alternative to inefficient flame and resistance heating. With induction, a specially designed coil is inserted into the bolt. Rapid, precisely controlled and localized heat is then induced directly in the bolt. The heat expands the bolt by an exact, pre-decided length, making it easy to remove the nut.What are the benefits?Foster Induction heat spreading is very accurate, due to the heat being generated within the component, you only heat the part you want to heat, and thus the bolt threads with nuts stay cold during the heating operation.The heating process is very fast and accurate there simply isnt enough time for heat to travel into the thread area. And with induction there is no risk of rods melting inside the bolts.In the bolt expansion process, focus on safety is vital for a consistent result and for avoiding damage to either personnel or the expansion bolt itself. It is very safe and easy method.Its precise and localized heat is faster and safer than resistance and flame heating process.Compact induction: You can move it around a workshop or factory floor.Flexible: It can be fitted with various coils for various bolt dimensions. Induction coils can be changed in seconds.Simple to operate: Easy access to bolts due to flexible coil.Reduced costs: Faster heat delivery, reduce the heating expenses compared to flame based high cost heating methods.Improved quality: Precise repeatability of heating cycles is assured. The same amount of energy is applied to each bolt. A constant energy level and heating time is guaranteed.Eco-friendly: No flames, no gas and virtually no radiant heat means a more comfortable, more productive working environment. Save energy-save environment.Brand : FOSTER, 100% Make in India 🇮🇳

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Foster |

| Color | Grey |

| Condition | New |

| Power | Electric |

| Application | Industrial |

| Certification | ISO 9001:2008, RoHS |

| Voltage | 230V |

| Warranty | 1yr |

| Capacity | 3kw |

| Heater Material | Metal |

| Size | Compact |

| Weight | 85 Kg |

| Driven Type | Electric |

| Port | Mundra |

| Delivery Time | 28 - 30 days |

| Packaging Details | Wooden |

Features & Benefits :

- Operator controls Easy to operate, no need for skilled operator

- Durable and compact design, loaded with safety features

- Low maintenance, easy to install and move

- Adopts the latest IGBT power units and frequency conversion control techniques with high efficiency, low energy consumption and higher output.

- Constant current and power control function providing higher reliability, sustainability and increased productivity.

- Hassle-free maintenance and minimal downtime.

- Advanced controls with diagnostic features. Improved production values through higher melting rates with homogeneous Melting due to auto stirring technology.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Type | Copper Wire Stripping Machine |

| Certification | CE Certified, ISO 9001:2008, RoHS |

| Application | Removing Insulation Copper Wire |

| Weight | Approx 50 Kg |

| Color | Blue, Grey, Light White |

| Voltage | 380V, 440V |

| Condition | New |

| Automatic Grade | Automatic, Semi Automatic |

| Power | 6-9kw, 9-12kw |

| Driven Type | Electric |

| Warranty | 1year |

| Brand Name | Foster |

| Technology | Latest IGBT Induction |

| Economical | Very |

| Energy Efficient | Highly |

| Port | Mundra |

| Payment Terms | Other |

| Delivery Time | 28 - 30 days |

| Packaging Details | 3 Layered wooden Packaging for ULTRA Safety |

Multi-strand CTC (Continuously Transposed Cable), an insulation-coated, copper wire used primarily in the production of large transformers, can be quickly stripped using Foster induction Ultrafast heat technology.

At a temperature of (600° C), the coating evaporates within seconds, making the process ideal for industrial applications such as the production of transformers or electrical machinery.

Prior to connection to the transformer, the ends of the wires must be stripped of this coating – a standard process that takes some time. This can be accomplished using a variety of traditional methods. However, sanding down the insulation is difficult if the wire has several layers, and a process using open flames carries certain health and safety risks.

Considering these factors, Foster induction heating is a quicker and safer alternative. In addition, heat is distributed evenly in the metal – regardless of the complexity of the wire’s winding – and causes fewer defects.